Products

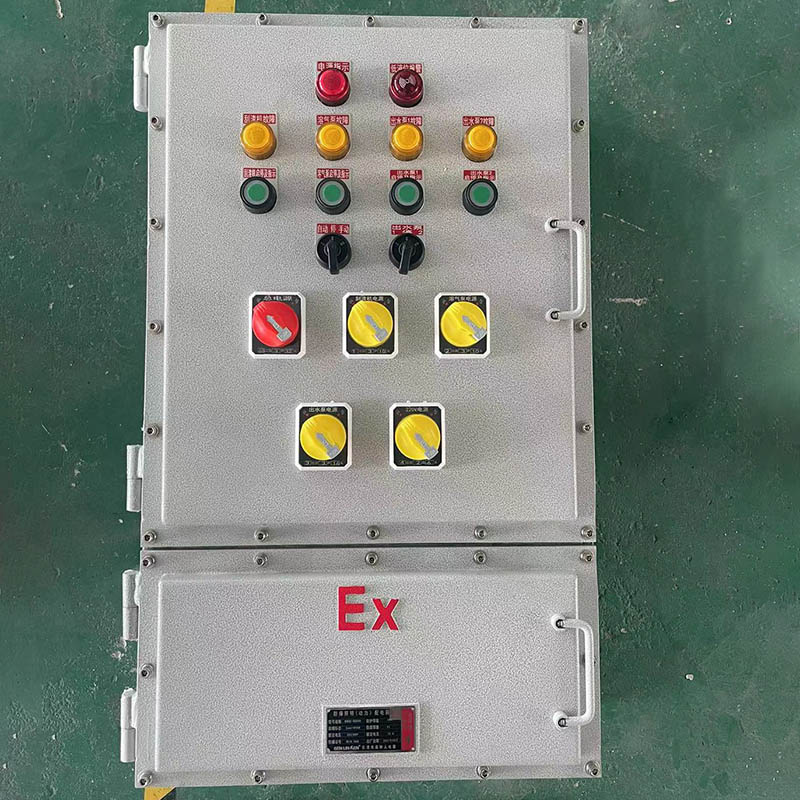

ATEX metal explosion-proof enclosure box

Product Description

Explosion-proof (also spelled explosion proof) is solidly constructed junction boxes for use in hazardous area locations. They house varying electrical components such as: terminal blocks, switches, transformers, relays and other arching & sparking devices. These boxes are engineered to contain an internal explosion from gases, vapors, dusts and fibers to maintain a safe surrounding atmosphere. They are corrosion resistant and maintain a high tolerance to extreme temperatures. These flameproof enclosures are the ideal solution for hazardous locations. Being explosion-proof, they will contain any internal explosions from spreading to the external environment, thus preventing injuries and the damaging of property.

Hazardous area explosion-proof and flameproof enclosures are classified into different protection ratings, depending on the location and the level of protection they offer. These ratings are based on the National Electrical Manufacturers Association (NEMA) standards, and also the International standard EN 60529 for Ingress Protection (IP) which indicate the level of protection against electrical hazards like corrosion, dust, rain, splashing & hose-directed water and ice formation.

Explosion-proof enclosures are designed with extended threaded flanges that cool and contain the explosion within the enclosure. Therefore, any potential electrical arc that occurs will not be spread to the external explosive atmosphere.

● It is safe and reliable in explosive atmospheres.

● An explosion-proof enclosure helps all the people working in the hazardous environment remain safe in case of an accident. It also minimizes the potential damage.

● The material used in the enclosure is durable. It has high impact resistance.

● It complies with the highest safety standards.

● It has a high degree of protection.