Growing demands for safety and compliance in hazardous environments have led to a surge in the popularity of ATEX metal explosion-proof enclosures across industries. These specialized enclosures are designed to provide protection against potential explosions and are becoming an important part of ensuring workplace safety and regulatory compliance.

One of the main reasons for the increasing popularity of ATEX metal explosion-proof enclosure boxes is their ability to mitigate the risks associated with explosive atmospheres. These enclosures are constructed from rugged materials and engineering to contain and contain explosions, preventing them from igniting surrounding flammable gases, vapors or dust. They therefore play a vital role in protecting people, equipment and facilities in environments with explosive hazards.

In addition, strict hazardous area classification regulatory requirements and standards drive the adoption of ATEX metal explosion-proof enclosures. Industries such as oil and gas, chemical processing, pharmaceuticals and mining must adhere to strict safety regulations to protect workers and assets from the potential hazards of explosive environments. ATEX-certified enclosures ensure that they meet the necessary safety standards and are suitable for use in hazardous areas, ensuring compliance with regulatory requirements.

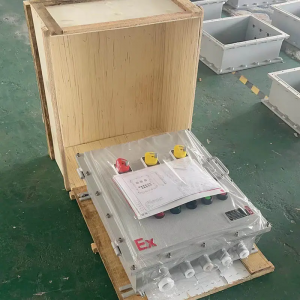

In addition, the versatility and adaptability of ATEX metal explosion-proof enclosures make them increasingly popular. These enclosures are available in a variety of sizes and configurations, allowing customization to fit different equipment and applications in hazardous environments. Whether housing electrical components, control systems or instrumentation, ATEX enclosures provide reliable solutions to protect critical assets in unstable environments.

As industries continue to prioritize safety and risk mitigation in hazardous environments, demand for ATEX metal explosion-proof enclosures is expected to continue. With their proven ability to enhance workplace safety and regulatory compliance, these specialized enclosures have become an indispensable asset for industries operating in potentially explosive environments.

Post time: Mar-26-2024